Pehel Dis‑In‑Cel Croscarmellose Sodium - A Competitive Alternative to Ac‑Di‑Sol.

- Pranav Zota

- Aug 7, 2025

- 4 min read

Background - Role of croscarmellose sodium

Croscarmellose sodium (CCS) is an internally cross linked polymer of sodium carboxymethyl cellulose used as a super disintegrant in pharmaceutical tablets and capsules. It appears as a white, fibrous, free flowing powder. The cross linking makes CCS insoluble but hydrophilic and highly absorbent. When tablets contact aqueous media, CCS rapidly absorbs water, swells, and creates hydrostatic pressure that breaks up the dosage form, thereby accelerating disintegration and drug dissolution at low use levels (1 - 2 %). Its disintegration performance depends on factors such as particle size, degree of substitution and the ratio of basic to acidic substituents. Published research shows that CCS has one of the highest water sorption and swelling capacities among disintegrants. These properties are critical for tablet breakup.

Benchmark product - Ac‑Di‑Sol®

Ac‑Di‑Sol (IFF/FMC) is the best known CCS brand. According to the manufacturer, Ac‑Di‑Sol is an internally cross linked sodium carboxymethyl cellulose that is insoluble and hydrophilic and exhibits excellent water uptake and rapid swelling, enabling rapid tablet disintegration at low concentrations. The powder has a fibrous morphology and low moisture/water soluble content.

Patent data on Ac‑Di‑Sol (Lot TN07817522) report a particle size distribution of D10 = 17.53 µm, D50 ≈ 44–45 µm and D90 ≈ 115 µm. Its high swelling ability allows tablets to disintegrate quickly. However the swelling and water uptake decrease in acidic media (pH ≈ 1), which can slow disintegration.

Pehel’s offering - Dis‑In‑Cel

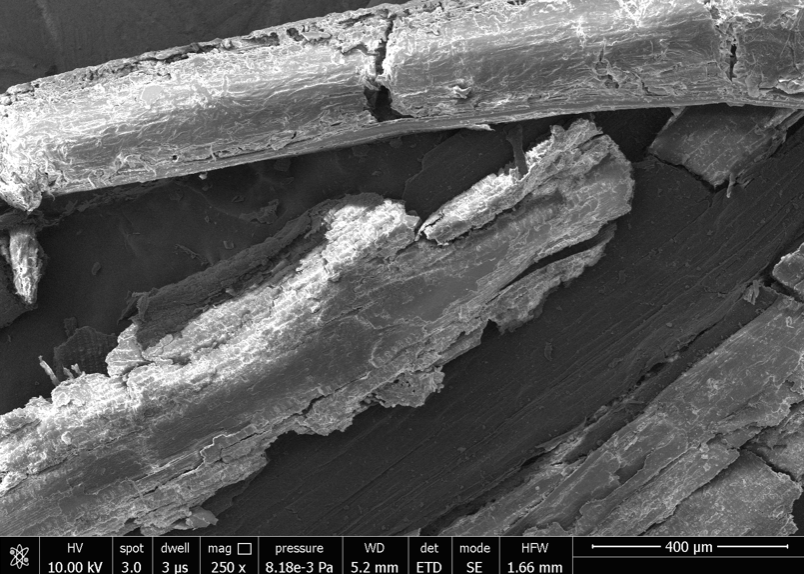

Pehel Specialities manufactures Dis‑In‑Cel, a premium CCS designed to match or surpass the performance of Ac‑Di‑Sol. Dis‑In‑Cel is produced from cotton linters and is an internally cross linked sodium carboxymethyl cellulose. The product is a white, fibrous powder with long fibres, ensuring superior wicking and rapid tablet disintegration. Dis‑In‑Cel is engineered for rapid swelling and excellent water wicking so that it achieves high efficacy at low concentrations (typically 1–2 %).

Particle‑size comparison

Table 1 compares the particle‑size distribution (PSD) of Pehel’s fibrous CCS (measured by laser diffraction) with the published PSD for Ac‑Di‑Sol®. Pehel’s material has D10 ≈ 7.15 µm, D50 ≈ 45 µm and D90 ≈ 132 µm. The D50 is almost identical to the Ac‑Di‑Sol median (44–45 µm), while D90 is slightly higher, indicating a broader upper tail. Pehel’s D10 is lower (finer fraction) but still within pharmacopeial limits.

Product | Reported D10 (µm) | D50 (µm) | D90 (µm) | Comment |

Dis‑In‑Cel (Pehel, cotton‑linter grade) | 7.15 | ≈45 | ≈132 | Laser diffraction measurement Lower D10 gives more fine particles, aiding wicking. |

Ac‑Di‑Sol® (FMC/IFF) | ~17.5 | 44–45 | ~115 | Patent for Ac‑Di‑Sol reports D10 = 17.53 µm, D50 = 44.45 µm and D90 = 114.67 µm |

General specifications

Pehel’s specifications for Dis‑In‑Cel align with USP/Ph.Eur. monographs. Key parameters include:

Origin - cotton linters (long fibres), (wood pulp grade also available for Non GMO)

Identification- IR and other tests comply with pharmacopeia.

Water soluble material - 1.0–5.5 %

Degree of substitution - 0.63–0.85

Loss on drying – not more than 6 %

pH (1 % suspension) – 5.9–7.0.

Particle size specification – D10 ≤ 25 µm; D50 = 25–55 µm; D90 ≥ 60 µm.

These specifications, along with low heavy metal and residual solvent limits , ensure global compliance.

Evidence of comparable performance

Swelling and water uptake

Research comparing super disintegrants shows that sodium starch glycolate has the highest swelling, followed by croscarmellose sodium; crospovidone. The same study found that the swelling mechanism is dominant for CCS, contributing to rapid disintegration. Another study investigating hydrochlorothiazide tablets confirmed that water uptake and swelling are key functions of super disintegrants and that the high swelling capacity of CCS (Ac‑Di‑Sol) is pH dependent. These findings indicate that any CCS with similar microstructure and particle size will exhibit similar swelling driven disintegration.

Fibrous morphology and wicking

Multiple independent sources describe CCS as a white, fibrous, free‑flowing powder. The fibrous nature provides excellent water wicking, allowing liquid to penetrate the tablet quickly and enabling rapid disintegration. Pehel’s cotton linter origin results in longer fibres that promote superior wicking and rapid tablet breakup. These morphological features mirror those reported for Ac‑Di‑Sol by its manufacturer.

Processability and dosage form flexibility

Ac‑Di‑Sol is reported to perform consistently across direct compression, dry granulation and wet granulation due to its low moisture content, low water soluble content and fibrous structure. Generic CCS specifications ensure compatibility with typical excipients like dicalcium phosphate and microcrystalline cellulose. Pehel’s Dis‑In‑Cel meets the same particle size window and offers identical morphology, so it can be expected to behave similarly during direct compression and granulation.

Comparative summary

Particle size distribution: Dis‑In‑Cel’s D50 (~45 µm) almost matches Ac‑Di‑Sol’s D50 (44–45 µm). The slightly broader upper tail (D90 132 µm vs 115 µm) is within USP limits and should not adversely affect disintegration.

Morphology: Both products are white, fibrous powders derived from cross‑linked sodium carboxymethyl cellulose. Pehel’s cotton linter grade yields longer fibres for efficient wicking.

Swelling/water uptake: Literature indicates that CCS exhibits high swelling capacity; it ranks only slightly below sodium starch glycolate. Since swelling is strongly related to particle size and microstructure, Dis‑In‑Cel’s similar PSD and morphology suggest comparable swelling and disintegration.

Regulatory compliance: Dis‑In‑Cel meets pharmacopeial limits for degree of substitution, water‑soluble content, heavy metals, loss on drying and pH. Ac‑Di‑Sol’s specifications (according to the same monographs) are similar.

Manufacturing and support: Pehel supplies Dis‑In‑Cel with GMP certification, full regulatory documentation and competitive pricing.

Strategic position and recommendation

Pehel’s Dis‑In‑Cel is deliberately engineered to be identical or near identical to Ac‑Di‑Sol. The particle‑size distribution is matched to the industry leader, and the material is produced from high‑quality cotton linters to replicate the fibrous morphology that confers rapid wicking and swelling. Literature demonstrates that CCS performance is primarily governed by particle size and microstructure; with a nearly identical D50 and similar swelling capacity, Dis‑In‑Cel should deliver tablet disintegration and dissolution performance equivalent to Ac‑Di‑Sol. Pehel further offers two origin options (cotton‑linter and non‑GMO wood pulp) to satisfy different regulatory requirements.

Opportunities

Market gaps – Ac‑Di‑Sol has global reach, but supply can be concentrated. Dis‑In‑Cel provides a competitive alternative with identical performance, enabling distributors to offer formulators a reliable second source and mitigate supply risks.

Cost advantage - Pehel leverages Indian manufacturing to offer European‑grade CCS at competitive prices.

Regulatory support - Pehel supplies complete regulatory dossiers, quality agreements and technical assistance, easing qualification for formulators.

Technical marketing - Dis‑In‑Cel’s cotton‑linter origin and longer fibres can be highlighted as a performance differentiator for fast‑disintegrating formulations.

Conclusion

Croscarmellose sodium remains a critical super disintegrant for immediate release dosage forms. Published evidence shows that performance is tightly linked to particle size and fibrous morphology. Pehel’s Dis‑In‑Cel matches the benchmark Ac‑Di‑Sol in median particle size, fibrous structure and swelling mechanism. With regulatory compliance, competitive pricing and strong technical support, Dis‑In‑Cel provides distributors and formulators with a high performing alternative to established CCS brands.

Comments